SUPERIOR SOLUTIONS FOR MEDIA FILTERS

- Designed and Built for Industrial Applications

- Bronze Pump and Basket Strainer

- NEMA 4 rated Brass Actuator Valves

- NEMA 4 rated UL Listed Control Cabinet with Allen Bradley Processor

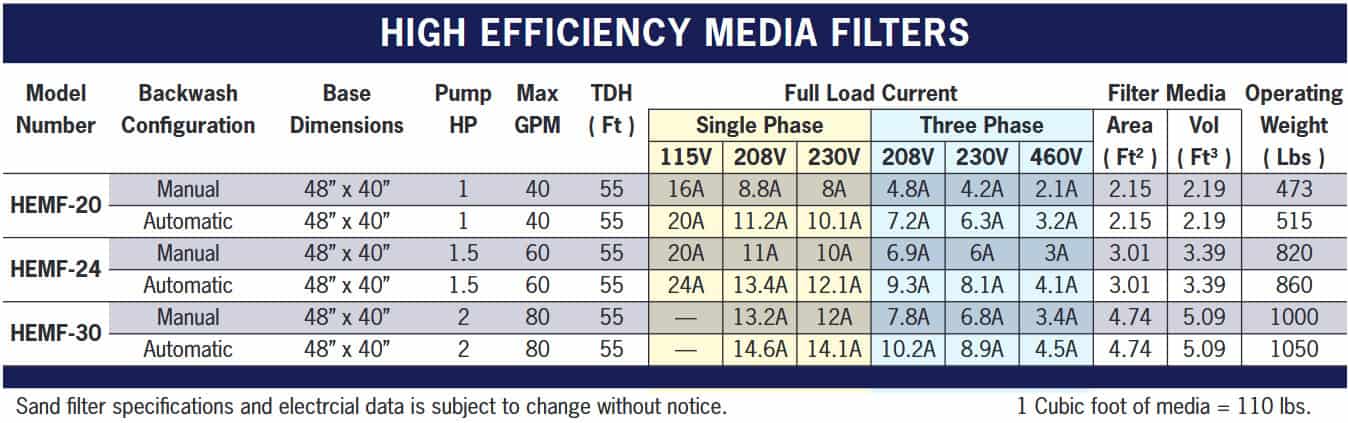

High Efficiency Media Filters

Process Cooling Systems High Efficiency Media Filters are configured for either manual or automatic backwashing of the filter bed and are self-contained to provide efficient particulate filtration on systems with high particulate loading. Each filter includes a pump, motor, basket strainer, backwash valves, filter vessel and required controls for either manual or automatic backwashing of the filter bed. All components are rated for outdoor use, are factory assembled with interconnecting piping, and include UL listed electrical. Standard filters are configured for process water backwash but are available configured with city water backwash.

BASE:

High Density Polyethylene Pallet with 4 Way Access 3.6” Fork Slots and Grated Top

PUMP:

Self-priming pump complete with brass volute, pump shaft, and open-faced bronze impeller. Pump will be close coupled to a TEFC motor.

MOTOR:

TEFC, NEMA56 Industrial Frame motor. This motor offers consistent power to promote superior water circulation and filtration, safety feature protecting unit from overload, and a standard drip proof seal to minimize seal burnout and provides for easy maintenance. UL Recognized; CSA Certified. 3 Year Warranty.

STRAINER:

FACEPIPING:

Manual Backwash: Brass piping assembly complete with influent / effluent pressure gauges (0-60 PSI liquid filled), brass interconnecting piping between pump discharge and valve assembly, Schedule 80 PVC filter vessel inlet and filter vessel outlet piping.

Automatic Backwash: Brass piping assembly complete with filter vessel pressure gauge (0-60 PSI liquid filled), brass interconnecting piping between pump discharge and valve assembly, Schedule 80 PVC filter vessel inlet and filter vessel outlet piping.

VALVES:

Manual Backwash: 3-Way manual bronze body ball valve with PTFE seals. Valves will be connected together with a mechanical linkage and a common actuator handle.

Automatic Backwash: 3-Way On/Off forged brass nickel-plated body, 304 stainless steel ball and stem, PTFE seats, L-port, 24-240 VAC, and NEMA 4 rating with Fail Safe actuator.

FILTER VESSEL:

Filter vessel consisting of an inner shell of fiberglass reinforced polyester resin wound over with fiberglass filament. The unit features an inflow diffuser for even distribution of the water flow across the filter bed, and hydraulically balanced PVC internal laterals to maximize water flow and filtration. The filter vessel is fitted with a manual drain fitting, large filter base for stable floor mounting and a manual pressure relief valve. The filter vessel is rated for 50 psi maximum allowable working pressure.

MEDIA:Silica Filter Sand

- Effective Size:0.72mm

- Uniformity Coefficient: 1.7

CONTROLS:

Manual Backwash

- Manual Motor Protector

- NEMA 4 Rated

- Motor Starter with Overload and Short Circuit Protection

- Fused Disconnect Switch

- On/Off Selector Switch for Pump

Automatic Backwash:

- Automatic Backwash Control Panel

- NEMA 4 Rated

- Motor Starter with Overload and Short Circuit Protection

- Transformer to convert primary supply to 24 VAC control power for the valves

- Through the door disconnect

- HOA switch for pump motor

- Differential pressure switch mounted on backside of control panel.

- System Alarm Package

- Motor Overload Trip, Backwash (Pressure switch activated twice in a 6 hour period), Modulating Valve Fault, and Pressure Switch Fault Alarms